METAL SAWING SOLUTIONS DESIGNED AROUND CUSTOMER NEEDS

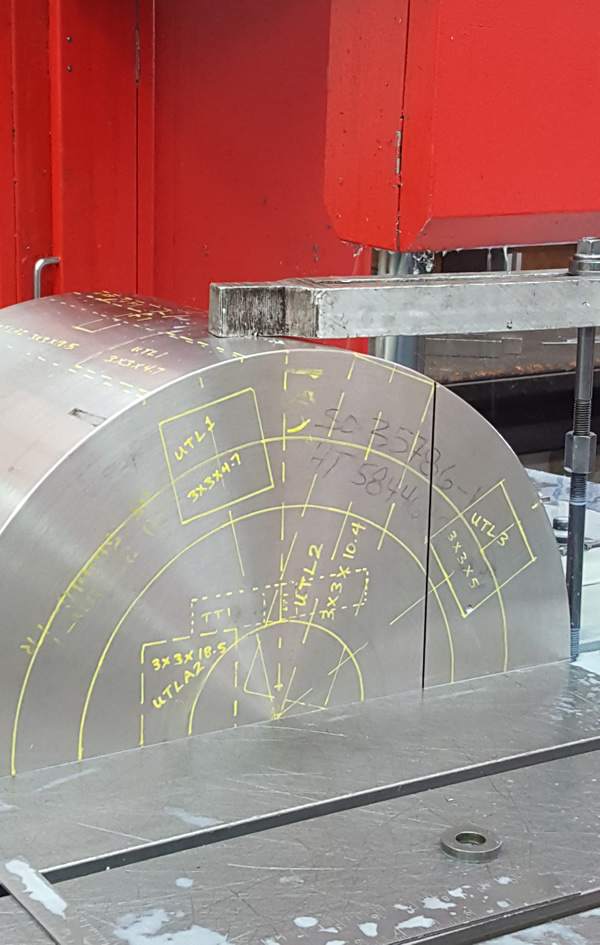

Cutting Specialists, Inc. is a leader in saw cutting hard metals in the Western USA. We work with all types of hard metals and have significant experience in cutting titanium and Inconel for use in aerospace components. Our capabilities include common and uncommon cuts of round bar stock up to 25” diameter and steel plate stock up to 24” thick.

We also specialize in:

- Splitting of metal pipe

- Production of (WT’s) by cutting wide flange steel beams

- Tube cutting

- Angle cutting

- Miter cutting

- Bundle cutting

- Shape cutting

- Plate Cutting

- Round Bar Cutting

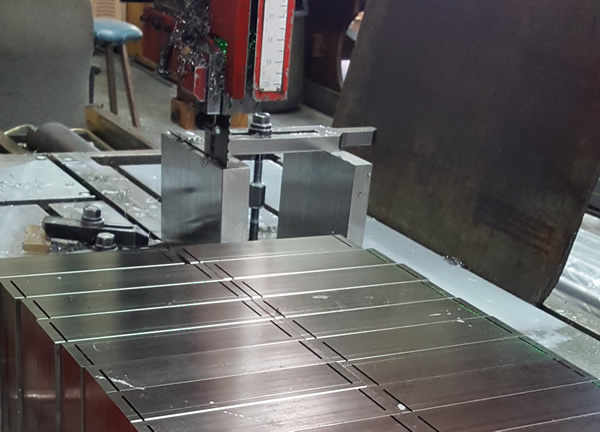

We can saw to special shapes and improve your turnaround time on jobs that would normally require expensive milling or machining time to remove large sections of material. Segmenting, slotting, mitering, plate sawing, cutting to length and cutting round bars into a rectangle or square shapes are just a few of the services we provide. No matter the job, Cutting Specialists, Inc. provides square, clean, saw cutting that reduces the need for secondary operations and provides safe material handling conditions for our customers.

SAW CUTTING IN WASHINGTON STATE

Cutting Specialists, Inc. is a leading provider of close tolerance, saw cut hard metal components in the Greater Seattle, Washington region. Our precision round bar and steel plate cutting, processing, and fabrication services are available to companies in the Puget Sound region, and to clients throughout the Western United States.

OUR METAL FABRICATION PROCESS

Less is more with Cutting Specialists, Inc., especially when it comes to the hard metal saw cutting. Our goal is to trim the excess from both metal components and various fabrication processes to make it easier for our clients to be more productive and profitable.

We start by consulting with our customers to understand their project goals. Then we direct every job to our team of experienced craftsmen, who are highly trained to process the pipe, round bar, and steel plate of your choosing into a perfect execution of your drawing. Finally, we expertly prepare the finished metal part for packaging and delivery.

PACKAGING AND PRESENTATION

Cutting Specialists, Inc. goes well beyond the main task of saw cutting metal components just to match client specifications. One of our concerns is the important and often overlooked detail involved in the presentation. We want our customers to receive a part in the best possible condition to support safe and easy handling on their shop floor. We make sure that our finished metal cut part is clean and free of all metal shavings, placed onto an equally clean and strong pallet, and securely packaged to withstand damage or dirt, and made easy to transport. All our component preparations promote a seamless handoff of product to our clients, which in turn brings value to their bottom line.

JUST IN TIME DELIVERY

Depending on client needs, we pickup, receive, warehouse, and deliver all customer products from our 11,600 square feet of warehouse and shop space in Tukwila. We will pick up clients’ metal product, or receive it at our facility for processing, then store it in our warehouse ready for pick up or just in time delivery, using our 24-foot flatbed truck.

EQUIPMENT CAPACITY

Cutting Specialists, Inc. continually invests in modern saw cutting technology and operates 18 heavy-duty band saws and cold saws with the capacity to cut any type of steel. Our capabilities include rounds up to 25” diameter and steel plate up to 24”. We also cut long lengths of steel as required for beam splitting, or splitting pipes with tight tolerances over a long traverse. View our current equipment selection.